Its so simple even a “CaveMan can use it”

The Shop-Talk Back-Plotters are the real heart and soul of the Shop-Talk CAD/CAM programming system. CNC programmers knows the value of Tool Verification when manually editing their CNC programs.

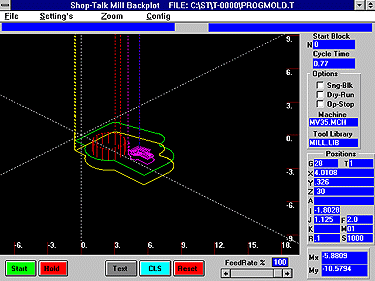

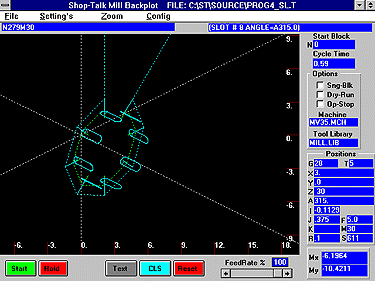

The Back-Plotters are great for Process Routing Engineers. Engineers writing process routings can load any ASCII NC tape file to view how the programmer actually machined the part. You also get a better estimate of the actual cycle time for machining the part. Your machine file contains the information for tool changes and rapid traverse rates providing accurate cycle times. The Mill Back Plotter also allows you to back plot files that contain subprograms for FANUC or FADAL. A work offset table is also provided for viewing multiple part zeroes. Our Back-Plotters support G54-G59, or E1-E99 work offsets.

After editing, go back to the plotter and check the new results. The back-plotter has many options and configurations for any type of machine. You set parameters for each machine tool in a machine file. Different modes of plotting define the speed of the plot including a single block option. When the tool changes, the plotter automatically changes the drawing color. Rapid moves are drawn by a dotted line and cutting moves are drawn by a solid line. You can start the plot at any block number in the file or from the beginning. The Mill-Cam Back-Plotter allows you to view in X&Y, X&Z, Y&Z, or Isometric. The Mill Plotter also displays 4th Axis, A or B moves.

CNC Mill Tool Simulation & Verification Back Plotter