Its so simple even a “CaveMan can use it”

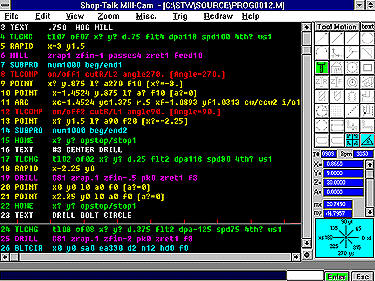

Shop-Talk Mill-Cam is a simple conversational 2½ Axis programming system with 4th axis positioning, 4th axis y wrap mill functions, thread milling and engraving. Mill-CAM is the simplest Conversational Program on the market today. Its easy to use because it works just like a machinist thinks. The programmer enters simple English text commands using the same logic your CNC machine uses.

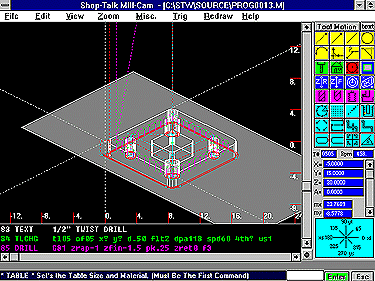

Shop-Talk Mill-Cam features pull down menus, on-line help, completely icon-driven questions and answers. Graphics are drawn as you answer the questions. Although Mill-Cam doesn't require any geometry to be drawn prior to using it, you can. The Shop-Talk CAD program can be used to draw the part geometry which can be imported into Mill-Cam to generate the tool path. Mill-CAM Comes with a universal post builder to configure your post processors G-Code any way you like it. Additionally, the output can be generated for many different controls, including but not limited to:

FANUC, YASNAC, MITSUBISHI, FAGOR

SIEMANS, ACRAMATIC, GE, AB

SMART ICON DESCRIPTIONS

On the right side of the screen are the Smart Icons. The Smart Icon Palette will display the icons as they become applicable. This helps to guide you through the correct programming sequence of events. The Smart Icons include:

Rapid

Point

Line

Circle

Unknown Point

Arc

Rapid Z

Feed Z

Home

Tool Comp

Mill

Drill

Bore

Thread Hob

Define Point

Bolt Circle

Grid & Double Grid Patterns

Rectangular Pocket

Circular Pocket

Rough Pocket

Mill-Cam Conversational Programming System

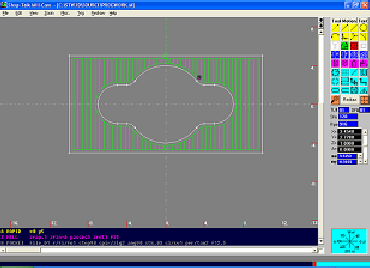

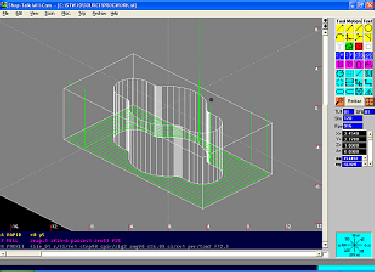

Pocket Milling: Shop-Talk now has a new Cad associative pocket milling routine. To create a pocket just draw the pocket in Cad or DXF in. Once you are in Mill-Cam load your drawing onto the table. Select mill and answer the questions. Then select the pocket icon and answer the questions. Shop-Talk will analyze the geometry and machine the pocket automatically. If you want to modify the pocket, just return to Cad and modify it. Add an island or slot. When you return to Mill-Cam and re-load the file it will analyze the geometry again and re-generate the tool path automatically.

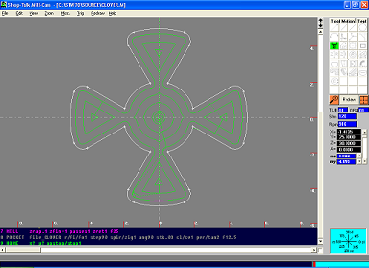

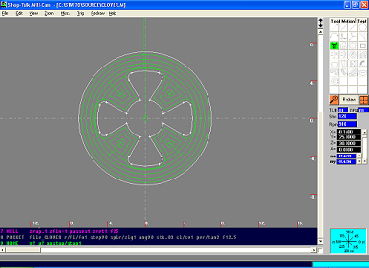

Take a look at the two pictures below. If you draw a pocket it assumes the inside is the pocket and machines it out. The picture on the right is the same piece of geometry but was modified by placing a circle around it. So now it assumes its an island.